Education - Part 4

Transport

Under construction

Introduction

Concept of Transport

Railroads are transport organizations. Their purpose, therefore, is the movement of entities (freight or goods and people) between two points in space-time. As such they are classified as carriers, a topic we discussed in What is a Railroad?. See also UNECE and Britannica.

Introduction

Concept of Transport

Railroads are transport organizations. Their purpose, therefore, is the movement of entities (freight or goods and people) between two points in space-time. As such they are classified as carriers, a topic we discussed in What is a Railroad?. See also UNECE and Britannica.

Purposes

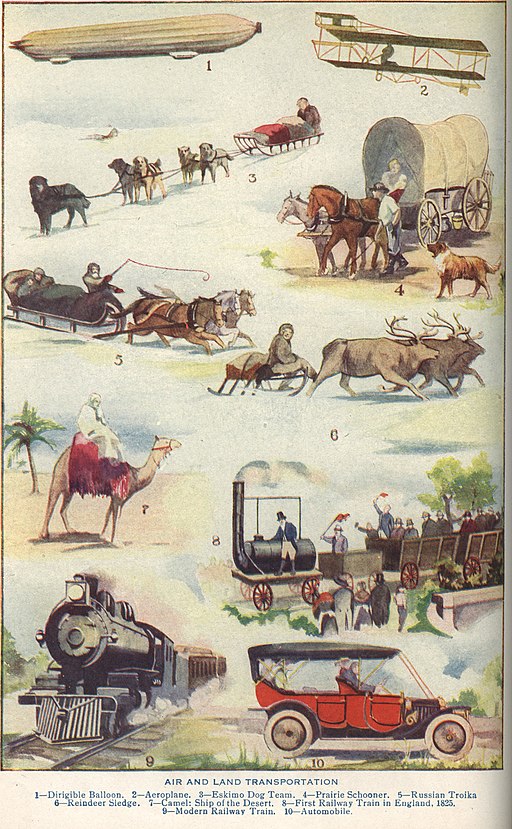

Transport or transportation is the means of moving things from one place to another place in some specified time. There are many sorts of transport, such as movement of water from a water tower to one's home, transport of voice messages from one person to another via a telephone system, movement of people and goods by truck, boat or rail, and so on, as illustrated below.

Transport or transportation is the means of moving things from one place to another place in some specified time. There are many sorts of transport, such as movement of water from a water tower to one's home, transport of voice messages from one person to another via a telephone system, movement of people and goods by truck, boat or rail, and so on, as illustrated below.

Here we are interested in transport by rail. See also UNECE RT.

Transport of goods by railroad involves the movement of large quantities from one place to another. This does not mean that a large quantity need be of just one kind of good in freight transport. Of course railroads transport car-loads of things such as gravel or milk, but bundles of individual items of all sorts, such as automobile parts or tires of various sizes and applications may also be transported, provided the bundle of goods is destined for a particular place.

Transport of people by railroad involves the movement of many people from one place to another such as from Philadelphia, PA to Baltimore, MD (although some may detrain at Wilmington, DE (while others may board there) or from Paris, France to Amsterdam, The Netherlands.

Transport also involves the matter of time. Railroad customers would rapidly move to alternative transport if a railroad could not deliver goods in a timely manner. In fact, it was railroads in England that helped establish standardized time by publishing railroad time tables that were based on Greenwich Mean Time (called railroad time) beginning 1847 December 1.

All the above-mentioned factors, together with manufacturing and production, constitute the field of logistics. According to the Council of Supply Chain Management Professionals (CSCMP), logistics is the process of planning, implementing and controlling procedures for the efficient and effective transportation and storage of goods including services and related information from the point of origin to the point of consumption, for the purpose of conforming to customer requirements and includes inbound, outbound, internal and external movements.

Legal Matters

In the United States, the Surface Transportation Board (STB) has broad economic regulatory oversight of railroads, including rates, service, the construction, acquisition, and abandonment of rail lines, carrier mergers, and interchange of traffic among carriers (see Carrier in What is a Railroad?). These various matters are beyond the scope of our discussion but may be mentioned as needed.

Shannondell Model Railroad

Shannondell Model Railroad is a transport system, but only on a limited model basis. It moves freight and people over its layout but does not actually carry on commerce with any of the entities modeled on the layout, except for a bit of advertising.

Freight Traffic Management and Control

Railroad Freight traffic management and control (FTM&C) is part of the discipline of logistics. FTM&C involves planning to transport goods over a fixed set of routes (trackage). This planning requires coordination with a number of entities, such as the manufacturer or producer, the wholesaler, the deliverer, forwarder and receiver. Coordination involves route (and alternate routes), timing (scheduling) and velocity control, necessary equipment (railroad cars, lift equipment, etc.), break-up and assembly of trains (yard work), crew assignments, weather, trackage conditions, un-planned incidents, and other factors.

Many approaches to FTM&C have been proposed and implemented. We discuss only the most modern of these approaches: Centralized Traffic Control (CTC), and Advanced Train Control System (ATCS). Nevertheless some background is essential for understanding these approaches.

Railroad Freight traffic management and control (FTM&C) is part of the discipline of logistics. FTM&C involves planning to transport goods over a fixed set of routes (trackage). This planning requires coordination with a number of entities, such as the manufacturer or producer, the wholesaler, the deliverer, forwarder and receiver. Coordination involves route (and alternate routes), timing (scheduling) and velocity control, necessary equipment (railroad cars, lift equipment, etc.), break-up and assembly of trains (yard work), crew assignments, weather, trackage conditions, un-planned incidents, and other factors.

Many approaches to FTM&C have been proposed and implemented. We discuss only the most modern of these approaches: Centralized Traffic Control (CTC), and Advanced Train Control System (ATCS). Nevertheless some background is essential for understanding these approaches.

Centralized Traffic Control

CTC consists of a centralized train dispatcher's office that controls railroad interlockings (discussed later) and traffic flows in portions of the rail system designated as CTC territory.

The train dispatcher (or team of dispatchers) is also responsible for safe and cost-effective movement of physical and human resource assets (trains and crews). This may involve a crew dispatcher responsible for tracking train crews and their assignments. This includes assignment of crews to trains based upon scheduled rosters as well as necessary adjustments based on rail traffic conditions and delays. The crew dispatcher is also responsible for checking that each train and engine crew are properly qualified for their assignments and have had proper rest according to labour regulations.

Other personnel in a CTC might be employed to handle specific sorts of events or circumstances (e.g., public safety, maintenance of way management and control).

CTC territory is all or part of a railroad operating division (an organizational unit focused on effective operation of a railroad within a defined geographic area). Some parts of a railroad may continue to operate under older rules and procedures. However, such parts must be compatible with rules and procedures used by the CTC. A CTC office will most likely be located near a busy yard or major station within the operating division.

The operation of CTC is mainly computer-based, employing databases, video displays, graphical user interfaces, telecommunication systems and networks, voice communication via network (mainly voice over Internet (VoIP)), and an array of track-side and on-board sensing, monitoring, controlling and reporting equipment to make possible near-fool-proof operation. We will examine some of these types of equipment later.

CTC consists of a centralized train dispatcher's office that controls railroad interlockings (discussed later) and traffic flows in portions of the rail system designated as CTC territory.

The train dispatcher (or team of dispatchers) is also responsible for safe and cost-effective movement of physical and human resource assets (trains and crews). This may involve a crew dispatcher responsible for tracking train crews and their assignments. This includes assignment of crews to trains based upon scheduled rosters as well as necessary adjustments based on rail traffic conditions and delays. The crew dispatcher is also responsible for checking that each train and engine crew are properly qualified for their assignments and have had proper rest according to labour regulations.

Other personnel in a CTC might be employed to handle specific sorts of events or circumstances (e.g., public safety, maintenance of way management and control).

CTC territory is all or part of a railroad operating division (an organizational unit focused on effective operation of a railroad within a defined geographic area). Some parts of a railroad may continue to operate under older rules and procedures. However, such parts must be compatible with rules and procedures used by the CTC. A CTC office will most likely be located near a busy yard or major station within the operating division.

The operation of CTC is mainly computer-based, employing databases, video displays, graphical user interfaces, telecommunication systems and networks, voice communication via network (mainly voice over Internet (VoIP)), and an array of track-side and on-board sensing, monitoring, controlling and reporting equipment to make possible near-fool-proof operation. We will examine some of these types of equipment later.

Advanced Train Control System

The Advanced Train Control System (ATCS) is a system specified by the Association of American Railroads. The system is defined in "Manual of Standards and Recommended Practices. Section K: Railway Electronics." Archived March 27, 2009, at the Wayback Machine. AAR publications are usually available to members for a fee, so access to the above publication is controlled.

ATCS is railroad independent whereas CTC is not. This means that the implementation of ATCS by one railroad will be compatible with that implemented by any other railroad.

The ATCS architecture is comprised of five major subsystems. Four of these subsystems are: Information Processing System (or Central Dispatch Computer) resident in the central dispatch office; On-board Locomotive System (or On-Board Computer); On-board Work Vehicles System (or Track Forces Terminal); In-The-Field System (or Wayside Interface Unit). These four subsystems collect, process, and distribute data with minimal input from dispatchers, enginemen, and foremen. The fifth system is the Data Communications System, which integrates the various information processing subsystems together and significantly reduces the need for voice communications. This is called the “ATCS keystone system”.

ATCS is designed for modular and step-wise implementation so as to permit each railroad to avoid the "all at once" approach to automation. Each railroad can choose to implement ATCS according its needs and resource availability within the architecture of ATCS.

The primary ATCS functions are:

The Advanced Train Control System (ATCS) is a system specified by the Association of American Railroads. The system is defined in "Manual of Standards and Recommended Practices. Section K: Railway Electronics." Archived March 27, 2009, at the Wayback Machine. AAR publications are usually available to members for a fee, so access to the above publication is controlled.

ATCS is railroad independent whereas CTC is not. This means that the implementation of ATCS by one railroad will be compatible with that implemented by any other railroad.

The ATCS architecture is comprised of five major subsystems. Four of these subsystems are: Information Processing System (or Central Dispatch Computer) resident in the central dispatch office; On-board Locomotive System (or On-Board Computer); On-board Work Vehicles System (or Track Forces Terminal); In-The-Field System (or Wayside Interface Unit). These four subsystems collect, process, and distribute data with minimal input from dispatchers, enginemen, and foremen. The fifth system is the Data Communications System, which integrates the various information processing subsystems together and significantly reduces the need for voice communications. This is called the “ATCS keystone system”.

ATCS is designed for modular and step-wise implementation so as to permit each railroad to avoid the "all at once" approach to automation. Each railroad can choose to implement ATCS according its needs and resource availability within the architecture of ATCS.

The primary ATCS functions are:

- management of track occupancies through centralized route and block interlocking logic;

- issuance of movement authorities via the data link to equipped trains and work vehicles, and via voice radio to unequipped trains and work vehicles;

- tracking of equipped train location and track occupancies via the data link, and unequipped train location and track occupancies via voice reports and manual entry;

- speed enforcement for equipped trains (also called Positive Train Control);

- enforcement of limits of authority for equipped trains;

- pacing for fuel economy for equipped trains;

- monitoring and control of wayside measuring, monitoring and reporting units;

- reporting of equipped train diagnostics and operating parameters;

- general exchange of instructions and messages.

Track Occupancy

Obviously, two trains cannot occupy the same section of track at the same time. In fact, two trains must be separated by some distance to allow for stopping without coming into contact with each other, regardless of the direction of travel of each train.

Because economics play an important part in building and operating a railroad (railway), it is imperative that trackage be used as efficiently as possible. This means that the more trains that run on a given stretch of track (other things being equal) the better. Nevertheless, trains are of variable length, operate at different speeds and exhibit other characteristics that complicate the management of train traffic. So railroads have devised a variety of schemes for operating more trains per unit time on a section of track while at the same time ensuring that railroad assets are employed safely and judiciously. Let us examine some of these schemes.

Blocks and Block Signalling

Before block signaling was developed, train traffic control was managed either by Timetable, Timetable and Train Order or by Telegraph and Crossing Order (see Signalling).

These means of train traffic control were replaced by a concept known as Block Signaling (for basic concepts of signalling, see Railroad Signal Systems.

A block was originally defined by signalmen stationed at intervals (blocks) along a line (a defined section of track) and using stopwatches and hand signals to communicate to a train driver that another train had passed some number of minutes before, indicating to the current train driver to slow down (if need be) to increase the interval between the two trains. Of course, the signalman had no way of knowing if the preceding train had continued to run on schedule or if it had stopped for some reason. This led to rear-end collisions.

With the advent of telegraphy, it became possible for a signalman to send a message indicating that a train had passed and that the block it vacated was clear. At the same time, railroad track-side signals could be operated by the signalman to ensure that the signal showed “danger” when the block was not clear and “clear” when it was clear.

Today, automatic block signalling is used to indicate whether a block (or blocks) is clear (proceed signal). This involves automatic train detection, using various techniques to determine if a train is present. A common technique is to use the rails to carry an electric current (track circuit) so that when a train enters a block, the electric current is short circuited, indicating train presence. Once the train clears the block, the electric current is restored, indicating the block is clear.

Another technique of more recent usage employs devices called axel counters. These devices actually count the number of axels that have passed. By placing axel counters at the beginning and end of each block, one can determine if the same number of axels entering a block also exit the block. This prevents accidents caused by train separation.

At the same time axel counters make it possible to determine the speed of the train by using the number of axels per unit of time. For maximum speed accuracy, one would also need to know the precise type of car the axels support, since cars are of different lengths, may have trucks with more than two axels, etc. As will be seen a bit later on, track-side devices can precisely identify each car of a consist and even compare it with the consist as reported from the yard where the train was made up. It is also possible to determine train speed in other ways as we shall see later.

Blocks may be of “fixed” size or “moving” (dynamic). Fixed blocks may actually be of varying lengths, but are marked by some means of identification, such as fixed physical length or signal to signal. Many blocks on many railroads are of “fixed” block type defined as the space between successive line-side signals.

More modern dynamic or moving blocks are defined by computer, determined by the length of the train plus a safety zone before and aft the train that no other train may enter (except under specific orders from a dispatcher). Dynamic blocks obviate the need for track-side signals.

In any case, determining the “size” of a block depends on the following factors:

Because of the increasing length of freight trains (now sometimes a mile or more in length) dynamic (moving) blocks seem more applicable.

Before block signaling was developed, train traffic control was managed either by Timetable, Timetable and Train Order or by Telegraph and Crossing Order (see Signalling).

These means of train traffic control were replaced by a concept known as Block Signaling (for basic concepts of signalling, see Railroad Signal Systems.

A block was originally defined by signalmen stationed at intervals (blocks) along a line (a defined section of track) and using stopwatches and hand signals to communicate to a train driver that another train had passed some number of minutes before, indicating to the current train driver to slow down (if need be) to increase the interval between the two trains. Of course, the signalman had no way of knowing if the preceding train had continued to run on schedule or if it had stopped for some reason. This led to rear-end collisions.

With the advent of telegraphy, it became possible for a signalman to send a message indicating that a train had passed and that the block it vacated was clear. At the same time, railroad track-side signals could be operated by the signalman to ensure that the signal showed “danger” when the block was not clear and “clear” when it was clear.

Today, automatic block signalling is used to indicate whether a block (or blocks) is clear (proceed signal). This involves automatic train detection, using various techniques to determine if a train is present. A common technique is to use the rails to carry an electric current (track circuit) so that when a train enters a block, the electric current is short circuited, indicating train presence. Once the train clears the block, the electric current is restored, indicating the block is clear.

Another technique of more recent usage employs devices called axel counters. These devices actually count the number of axels that have passed. By placing axel counters at the beginning and end of each block, one can determine if the same number of axels entering a block also exit the block. This prevents accidents caused by train separation.

At the same time axel counters make it possible to determine the speed of the train by using the number of axels per unit of time. For maximum speed accuracy, one would also need to know the precise type of car the axels support, since cars are of different lengths, may have trucks with more than two axels, etc. As will be seen a bit later on, track-side devices can precisely identify each car of a consist and even compare it with the consist as reported from the yard where the train was made up. It is also possible to determine train speed in other ways as we shall see later.

Blocks may be of “fixed” size or “moving” (dynamic). Fixed blocks may actually be of varying lengths, but are marked by some means of identification, such as fixed physical length or signal to signal. Many blocks on many railroads are of “fixed” block type defined as the space between successive line-side signals.

More modern dynamic or moving blocks are defined by computer, determined by the length of the train plus a safety zone before and aft the train that no other train may enter (except under specific orders from a dispatcher). Dynamic blocks obviate the need for track-side signals.

In any case, determining the “size” of a block depends on the following factors:

- Line speed (the maximum permitted speed over a given section of line)

- Train speed (the maximum speed of different types of traffic: freight, passenger, etc.)

- Gradient (to account for longer or shorter braking distances)

- The braking characteristics of trains (different types of train have different inertial figures)

- Sighting (how far ahead a driver can see a signal for “fixed” blocks)

- Reaction time of the driver

Because of the increasing length of freight trains (now sometimes a mile or more in length) dynamic (moving) blocks seem more applicable.

Block Interlocking… linking together of all turnouts, signals, etc. to insure that the route a train is supposed to take is actually available when the train needs it. (more to come)

An Example

In order to give an idea of the operation of a system with some of the capabilities of the ATCS, we present a realistic but fictional description of a railroad with advanced computing and telecommunication capabilities in the following paragraphs. In development...

Maintenance Facilities

Either railroad owned or service company owned

Either railroad owned or service company owned

Passenger Traffic Management and Control

Other Transport topics to come, such as bill of lading, forwarding agent, warehouse receipt, delivery ...

Manufacturing and Service Facilities

Just list some near by: Altoona, Wabtec, Progress Rail, etc. Lists

Just list some near by: Altoona, Wabtec, Progress Rail, etc. Lists